Product Details

Busduct system, also known as busway or bus duct, is an advanced electrical power distribution system designed to efficiently transmit power in various fields (including high-rise buildings, factories, data centers, and public infrastructure). Compared with traditional power cables, busduct system provides a better and safer solution to meet modern power distribution requirements.

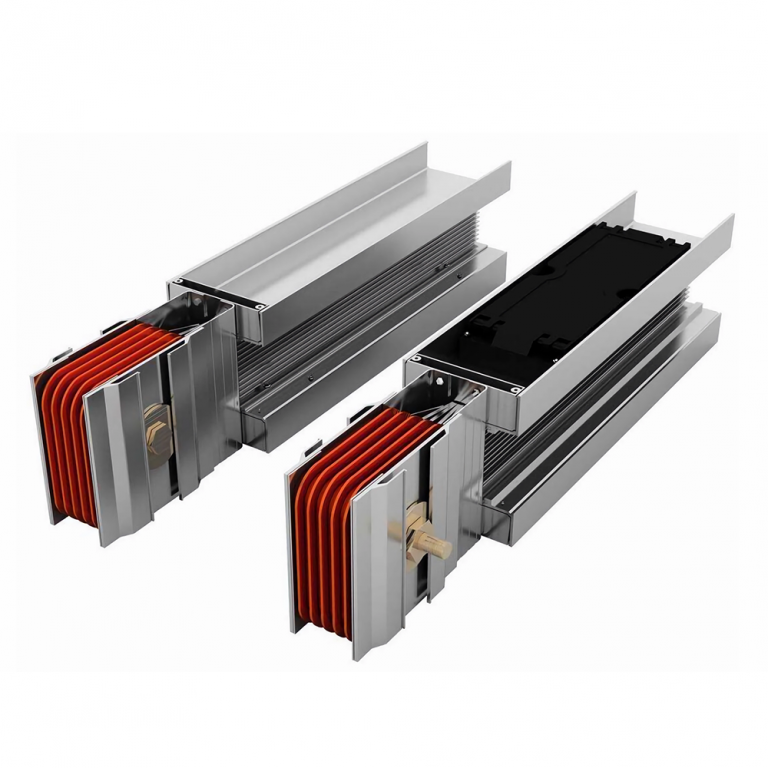

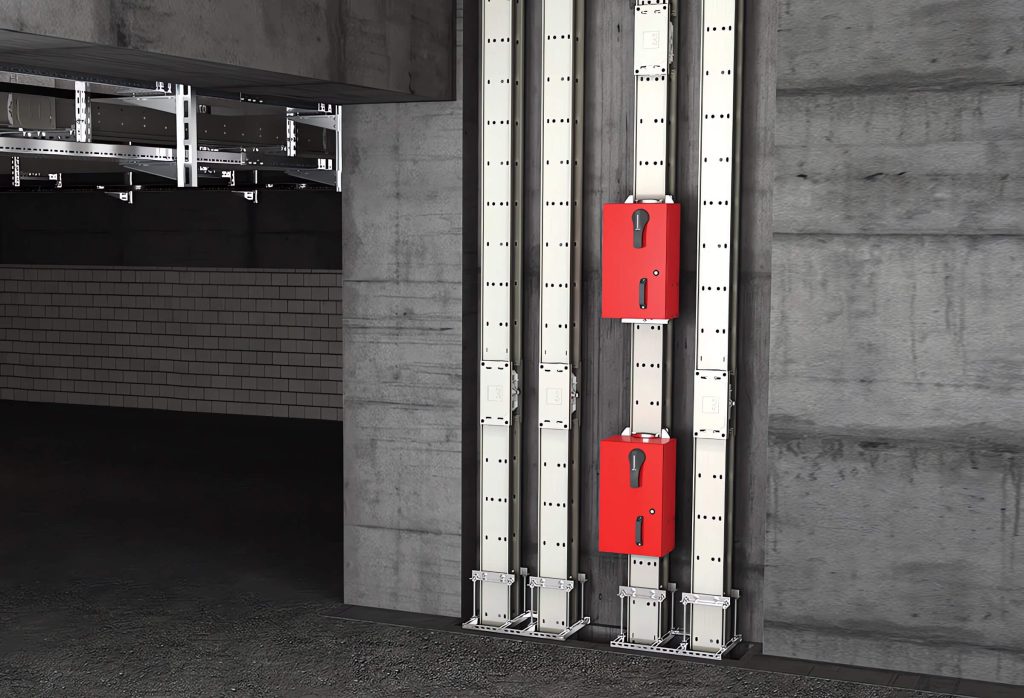

Busways consist of copper or aluminum conductor bars enclosed within an aluminum housing, the enclosure not only provides mechanical protection but also helps in bus duct’s heat dissipation. Class B rated (130°C) polyester films are used as the insulation materials, wrap around each bus bar, giving excellent separation of busbars, from phase to phase and phase to ground. Epoxy insulation is also available according to your needs. The entire busduct system includes straight lengths (feeder type and plug in type), elbows, flange end, expansion joints, tap-off units, reducer, and end closure. Each section is connected via bolt-on joints to ensure a safe and easy installation.

Busway systems have a lot of advantages compared with the traditional power cables. The lower impedance and energy loss provide greater transmission efficiency, the sandwich structure design of bus ducts helps save space for high-rise buildings or large industrial factories, and they’re easier to install or modify with reduced labor costs and downtime compared with traditional cables. The service time of busway is around 30-40 years, much longer than power cables. Besides, bus duct is almost free from maintenance after installation, not like the cables that need to be checked and replaced regularly.

Quality control in bus duct manufacturing is critical to ensure safety, reliability, and excellent performance of busduct in electrical power distribution systems. From raw materials inspection (bus bars must meet strict conductivity and purity standard, epoxy or polyester insulation films are checked for dielectric strength, thickness, and thermal resistance performance, aluminum enclosures need to be inspected for thickness, corrosion resistance, and mechanical properties), to manufacturing process control and finished products final inspection and testing (Dielectric Testing, Temperature Rise Test, Dimension Precision Inspection, IP Rating Tests), Each run of ETE bus duct needs to pass all kinds of tests to ensure absolute safety and compliance with industry standards such as IEC or UL certifications.

Why use busway system? Bus ducts offer an efficient solution that’s more reliable, space-saving, and cost-effective to meet all the needs and demands of today’s power distribution system that traditional power cables can’t keep up with. Now the busduct system is more and more popular and widely used in shopping malls, residential buildings, data centers, industrial plants, hotels, hospitals, airports and so on.

Specifications

| Product Name: | Busway |

| Product type: | Sandwich Type |

| Place of Origin: | Jiangsu, China |

| Brand Name: | ETE |

| Executive standard | IEC61439-6 |

| Certificate: | CE CCC RoHS Reach |

| Rated current(A) | 250A~6300A |

| Rated voltage Ue(V) | 1000V |

| Insulation | Epoxy or PET Film |

| Protection Level: | IP55 (with tap-off) ~IP67(without tap-off) |

| Rated frequency(Hz) | 50/60Hz |

| Conductor material: | Aluminum or Copper |

| Color | standard RAL7035 pale grey, adjustable as per preference. |

| Installation method | Horizontal hanging bracket, spring hanger |

| Packing | Wooden Case |

| Warranty: | 2 Years |